Across our businesses, ELANTAS operates globally with a well-balanced and diverse portfolio.

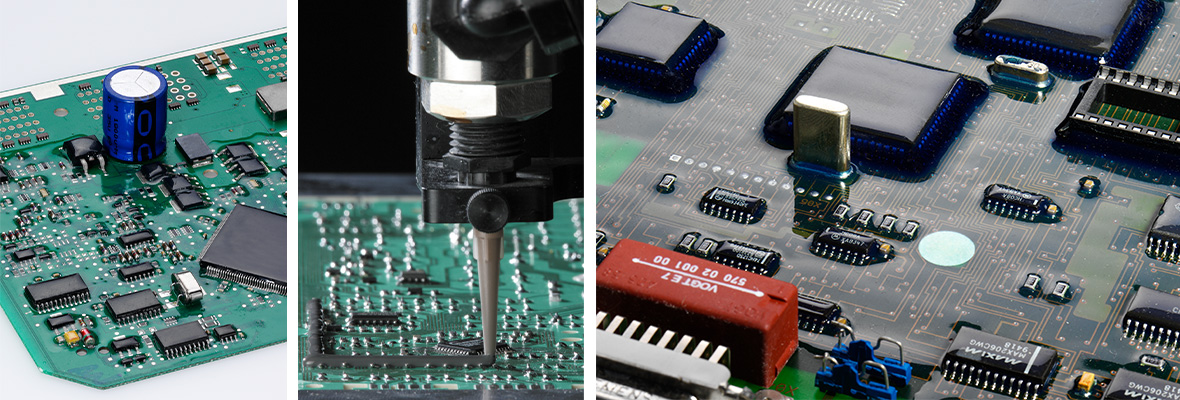

In the electronics industry, product sophistication and manufacturing techniques evolve quickly. Many top electronic assembly companies therefore rely on ELANTAS to deliver proven, reliable, and compatible material solutions which they need to stay competitive.

ELANTAS is uniquely positioned to supply the electronics industry with world-class materials and complete solutions for printed circuit boards (PCBs), with a major focus on thermal management solutions and PCB protection solutions. We believe in offering tailor-made solutions to meet market challenges and demands. We thus enable our customers to achieve competitive advantages as well as environmentally-responsible and cost-effective operations.

If you would like to find out more about our products, please contact

SalesSupport.ELANTAS.Beck.India@altana.com

In order to search for a particular product, please visit our product database.

In electronics, potting is a process of filling a complete electronic assembly with a solid or gelatinous compound for resistance to shocks and vibration and for protection against moisture and corrosive agents.

ELANTAS offers potting solutions in all chemistries, which include silicone, PU, and epoxy.

Key features of the potting systems:

- Un-filled and filled – silicone, EP, and PU

- Variable colours and viscosities

- Wide hardness range: Shore A 30 (highly flexible) -> Shore D 95 (highly rigid)

- Tg range -40 °C to 130 °C

- Thermal class up to 180 °C

- REACH- and RoHS-compliant (special products)

- Flame retardant

- Thermally conductive

- Excellent thermal shock and cycling characteristics

Products

Elan-tron®, Dobeckot®, Dobefil®, Dobeckan®IF, MICAREZ, SHIMOREZ, SHIMOCAST, and SHIMOKOTE.

Conformal Coatings

ELANTAS conformal coatings are suitable for many process methods including select coat, spray, dip, and selective flooding.

ELANTAS conformal coatings provide optimal protection for electronic assemblies against moisture, chemicals, mechanical stress, dust, contaminants, corrosive gases, and other impurities.

Cured film properties include:

- High temperature index (up to +200 °C @ 20,000 h)

- Excellent thin film dielectrics

- Protection against several environmental influences

- Very good chemical resistance

- Excellent PCB adhesion, withstanding several temperature cycles of -40 to +180 °C

Air Drying Resistant Coatings

BECTRON® PL4122 BLF is a lead-free coating range based on urethane-alkyd varnish for conformal coatings for printed circuit boards (PCBs) and hybrid circuits. BECTRON® PL4122 BLF products are free of aromatic solvents and meet the latest performance characteristics for electronics, including low pin corrosion and fast curing at oven and room temperatures. Conveyor oven systems permit very short cure times, below ten minutes.

Rapid Process Acrylic Coatings

BECTRON® PL1102 and PL1104 air-dried coating requires 15 minutes at +25 °C to give a good film for moisture and general protection for PCBs and related applications.

Waterborne Conformal Coatings

BECTRON® PL6100 is a modified alkyd coating with rapid heat curing or overnight air dry curing that provides the performance of solvent-borne coatings, without using VOCs.

Silicone

BECTRON® SC7575 is a VOC-free silicone coating with high thermal performance, very fast curing at

+90 °C possible.

BECTRON® SC7576 is a VOC-free silicone conformal coating for thin-layer applications, applied by crosscut nozzle, airless spray system.

Thermal interface materials include any material which is inserted between two substrates, where one substrate generates heat (electronic component) and the other substrate functions as a heat sink to improve the heat dissipation of an electronic assembly. Several kinds of thermal interface materials exist, which have different areas of application. These include thermal glues, thermal greases, thermal gap fillers, thermal adhesives, and thermal pads.

In response to the high demand for Thermal Interface Material (TIM), ELANTAS has developed a number of innovative materials.

If you would like find out more about our products please contact

SalesSupport.ELANTAS.Beck.India@altana.com