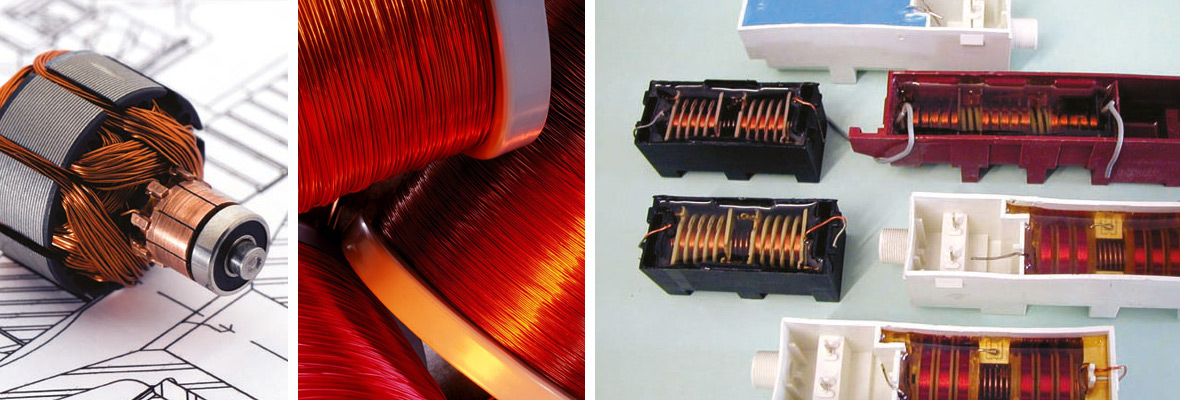

Primary Insulation

Electrical devices such as motors, generators, and transformers function on the basis of electromagnetic induction. The rotational or linear movement of such electrical rotary equipment is caused by electromagnetic fields, generated by electrical coils, and their mutual repulsion forces.

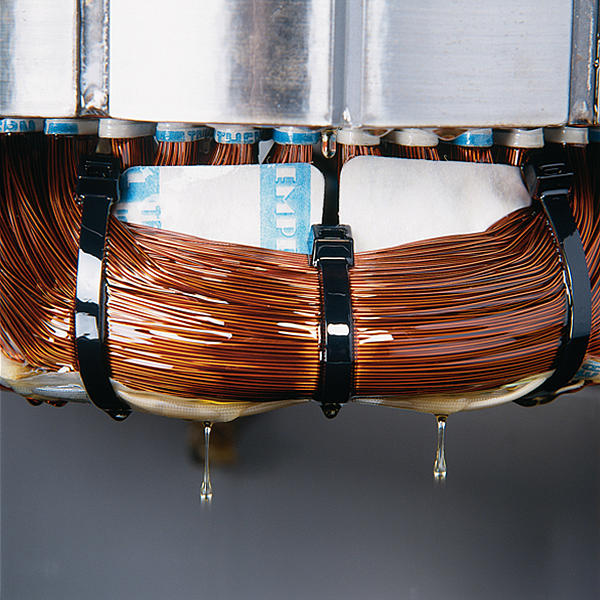

Where the actual enameling process is concerned,

the wire enamel is applied to the metal wire concentrically in several coating operations in a thermal coating process, so-called enameling process. The wire enamel is a varnish and consists of organic components (prepolymers) that react to cross-linked polymers during the baking and thus form an impermeable electrical insulation layer.

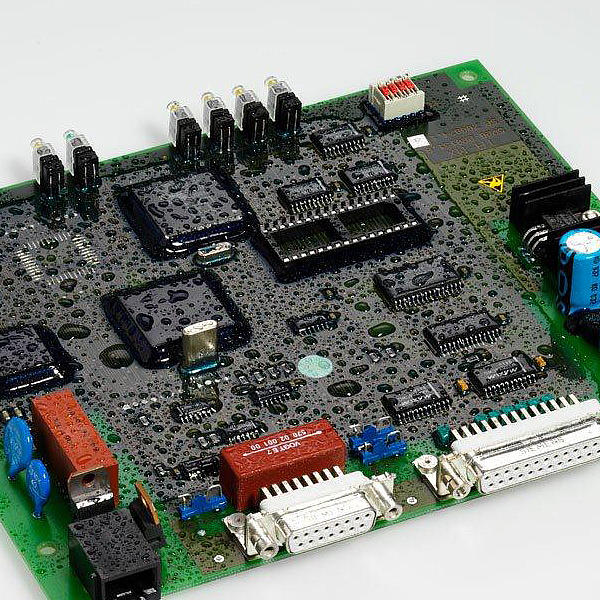

With static electrical equipment,

such as transformers or sensors, mutual insulation of the wires is necessary to maintain the electromagnetic field and thus to ensure the power or signal transmission. Apart from the basic electrical insulation requirement, this means depending on the end-use application high thermal and mechanical stability, flexibility, moisture resistance, and long service life of the insulation.

For a safe and stable function

of such rotary equipment, the metal wire, which is made chiefly from copper or aluminum, is concentrically enclosed with an initial insulating layer, the so-called wire enamel, prior to the winding process. This prevents direct electrical shorting between the individual wires and thus loss of the electromagnetic fields under all operating conditions.