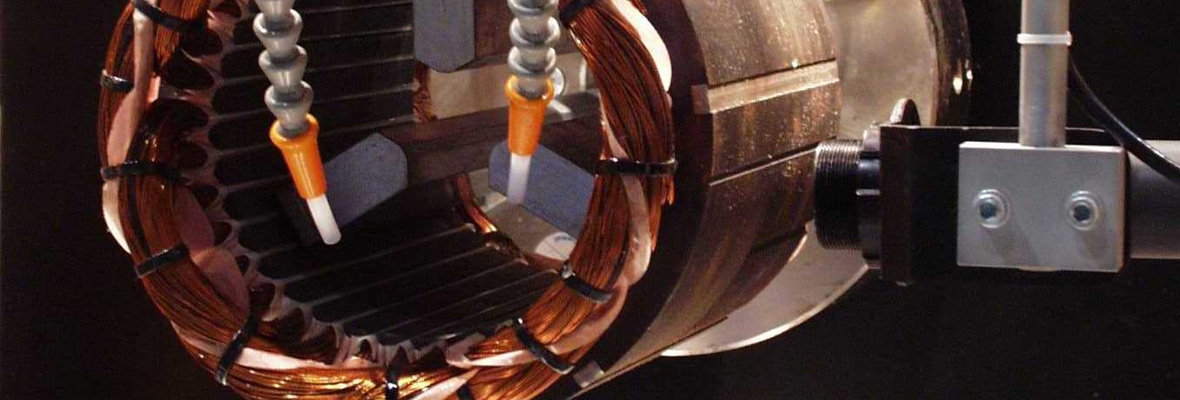

As the core part of an automobile, motor is expected to have an excellent performance with regard to instantaneous power, power density, overload resistance capacity and product life cycle. The application of insulating material enables a motor to deliver those properties, therefore, allowing EV/HEV automobile to be used regularly in a demanding environment such as high temperature, high moisture, salty condition.

Product Summary

For more than 20 years, we have been delivered outstanding solutions to EV/HEV market. Many innovated products from us have been applied and proven in the industry. Unsaturated polyesterimide resin is widely used because of its excellent electrical and bonding properties. Epoxy resin provides a good solution for hairpin motors and lamination adhesion &potting.We have a lot of experience on motor encapsulation.

Solutions For

- UL Recognition

- Outstanding Electrical Properties

- Compatibility with ATF & Other Materials (Slot Insulation etc.)

- Primary & Secondary Insulation Materials

- To Deliver Stator Potting Solution

| Product Name | Base Resin | Unique Characteristics | Viscosity @25°C | Cure Schedule | Application Method | Thermal Class |

| DOBECKAN FT 2015 EK HT | Unsaturated Polyesterimide | Single component, Low odor, High bond strength, High thixotrophy, the cured material displays very high resistance to tropical influences, solvent, oil and other chemicals | 800-1300 | 2-6 hours @120-150°C | VPI | 200°C |

| ELAN-PROTECT UP142 | Unsaturated Polyesterimid | Single component, high thixotropic, good penetration, low emissions, excellent heat resistance, strong centrifugal force resistance. Available in low viscosity, high thixotrophy and UV curing versions. | 900-1500 @23°C | 2 hours @150°C | Roll Dip/Dip/Trickle/VPI | 180°C |

| R2003S THIXO PRE-CAT | Unsaturated Polyester | High thixotrophy, good tank stability coupled with good bond strength, low shrinkage and chemical/moisture resistance. | 500-750 | 2-4 hours @150°C | VPI | 180°C |

| DOBECKAN FT 2015 EK LOW VOC | Unsaturated Polyesterimide | Single component, high thixotropic, good penetration, low emissions, excellent heat resistance, strongth centrifugal force. Available in high thixotrophy and UV curing versions. | 1000-1500 (23°C) | 1 hour @150°C | Roll Dip/Dip/Trickle/VPI | 200°C |

| DOBECKAN MF 8044 | Unsaturated Polyesterimide | Single component, good penetration, low emissions, excellent heat resistance, strong centrifugal force. Available in UV curing versions. | 6500-7500 (23°C) | 40 minutes @150°C | Dip/Trickle/VPI | 180°C |

| Pedigree 5180 POLYESTER RESIN | Unsaturated Polyester | Chemically promoted for low temperature cure, Low viscosity, Semi-flexible for vibration and noise suppression, UL recognized insulation systems up to Class 240, UV light fluorescent. | 150-200 | 30 minutes @120°C | Roll Dip/Dip/Trickle | 180°C |

| GRC 59-50MR EMULSION | Epoxy Emulsion | No VOC water based epoxy emulsion with high bond strength and excellent electrical properties. This material exhibits superb chemical resistance in harsh enviroments. Available in various non-volatile content versions from 10-50% | 50-500 | 2-6 hours @150-165°C | Roll Dip/Dip/Trickle | 180°C |

| EIP 235SG RESIN/EIP 235SG HARDENER | Epoxy | Good resistance for heat and mechanical shock,high resistance to chemicals and humidity. It can be cured at room temperature or by baking. Long shelf life before mixed. | 1950-3450 /200-300 | 24hours@25°C 3hours@40°C | Brush | 180°C |

| PED300S-65 | Unsaturated Polyester | Three components, Good resistance for heat and mechanical shock, high thermal conductivity. It can be cured at room temperature or by baking. | 25000-9000 | 24hours@25°C 2hours@90°C | Potting/casting | 180°C |

| E 88 M THERMOPOXY/ C 89 M HARDENER | Epoxy | Two components, heat curing filled epoxy resin system, superior impregnation property to reduce corona discharge notably. Excellent thermal shocking and high thermal conuctivity. Suitable for encpsulation of high voltage electrical components. | 65000-85000/ 20000-50000 | 1.5 hours @125°C | Potting/casting | 180°C |