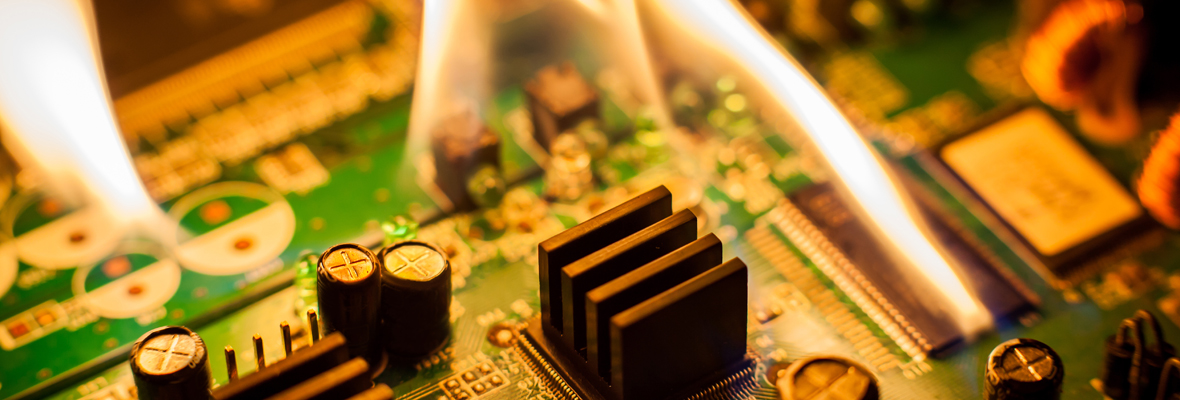

In the electronics industry miniaturization and greater levels of performance are key trends. The placement density of electronic components on the PCBs is constantly increasing, resulting in higher heat production, and even causing fire.

ELANTAS Europe has developed a series of thermally conductive casting compounds to counteract this problem.

This newsletter describes how to protect your electronic module with little effort.

This newsletter describes a series of thermally conductive, electrically insulating materials, so-called thermal interface materials (TIM).

These products are available as easy-flowing and self-levelling setting compounds. Besides good thermal conductivity, the materials also furnish additional corrosion protection.

The products described in the overview have the following properties in common:

2-component polyurethane, with different possible mixing proportions

Temperature range -50°C to +130°C

Flexible mechanical properties for stress compensation

Excellent electrical insulating properties

Self-extinguishing properties possible

Product | Thermal | Shore | Application | Special Features |

Bectron® PU 4568 | 1.1 | A ~90 | Thermal encapsulating. | easy-flowing and self-levelling |

ELAN-tim® CU 13 AV | 1.3 | D ~35 | Thermal encapsulating. | easy-flowing and self-levelling |

ELAN-tim® CU 16 DV | 1.6 | D ~33 | Thermal encapsulating. | easy-flowing and self-levelling |

*Coefficient of thermal expansion

All products above are manufactured on an industrial scale and are also available as samples.

For questions about the choice of appropriate materials, applications or sample request please feel free to contact us directly under bectron.ELANTAS.europe@altana.com

Learn more about our portfolio for electronic protection.