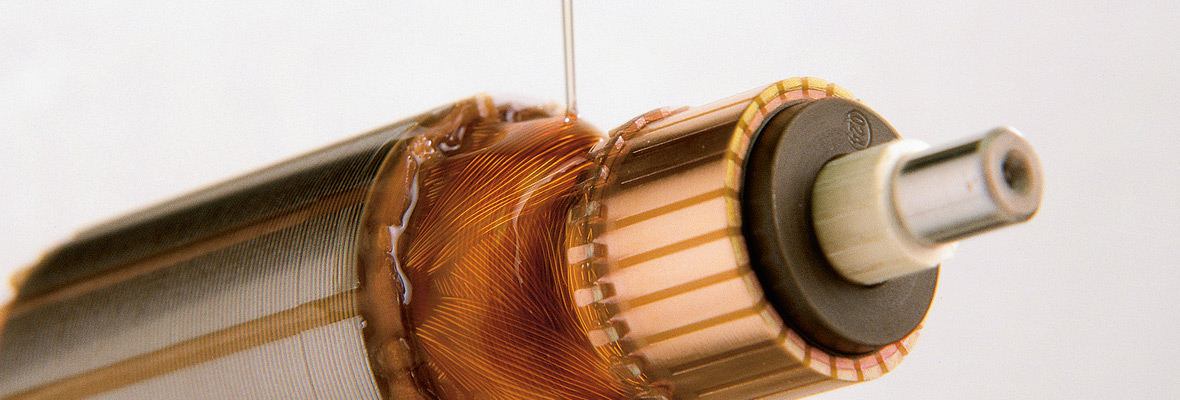

Trickle and Roll Dip application methods are typically used for the rapid processing of wire wound components. With these processes good penetration and resin uptake in the windings is achieved.

Resin is applied in a controlled, manner directly onto the pre-heated and rotating component allowing efficient penetration of the resin and rapid gelation.

Curing is then achieved either directly or in a secondary oven.

Do you need further information about our impregnating materials? Please get in touch with us. We are looking forward to your email to impregnation.elantas.europe@altana.com.

REQUEST TECHNICAL PRODUCT DATASHEET

REQUEST TECHNICAL PRODUCT DATASHEET

Typical ELANTAS Trickle / Roll Dip resins:

| Product | Viscosity | Temperature Index | Typical Cure Schedule | Description |

| ELAN-protect® UP 142 | 900 – 1500 mPa.s 23°C | 180 | 1 h / 150°C or 30 mins / 160°C | Single component, UL recognised, unsaturated polyester-imide resin, low viscosity, |

| ELAN-protect® EP 101# | 400 – 2500 mPa.s 25°C | 180 | 3 h / 165°C | Single component, UL recognised, epoxy resin, low viscosity, excellent moisture and chemical resistance. Suitable for low voltage electric motor stators. For dip, hot dip, dip-roll and trickle application. |

| Dobeckan® MF 8001 NV | 6500 – 7500 mPa.s 23°C | 180 | 2 h / 150°C | Single component, UL recognised, unsaturated polyester resin, monomer and VOC free, medium viscosity, environmentally compatible. For hot dip trickle and dip-roll application. |

| Dobeckan® MF 8005 | 850 – 1150 mPa.s 23°C | 180 | 30 min / 150°C or 15 min / 160°C | Single component, UL recognised, unsaturated polyester resin, monomer and VOC free, low viscosity, environmentally compatible, high reactivity, stable, for small and medium size motors. For dip, trickle and dip-roll application. |

| ELAN-protect® UP 240 | 140 – 160 mPa.s 23°C | 180 | 1 h / 140°C or 30 min / 160°C | Two component, unsaturated polyester resin, contains acrylate, high reactivity, for small to medium size automotive alternators. For trickle and dip-roll application. |

| Dobeckan® FT 1040/120 | 115 – 135 mPa.s 23°C | 180 | 30 min / 130°C or 15 min / 140°C | Two component, UL recognised, unsaturated polyester-imide resin, contains styrene, tough-hard material, for household machines and magnet wheels. For trickle application. |

| Dobeckan® FT 1080/… | 115 – 135 or 450 – 550 mPa.s23°C | 200 | 30 min / 130°C or 15 min / 140°C | Two component, UL recognised, unsaturated polyester-imide resin, contains styrene, high bond strength, for processing of armatures and rotors. For trickle application. |

| Dobeckan® FT 2001/… | 115 – 135 or 470 – 520 mPa.s23°C | 180 | 45 min / 130°C or 15 min / 150°C | Two component, UL recognised, unsaturated polyester-imide resin, contains styrene, excellent bond strength, for high speed power tools, starter motors and dynamos. For trickle application. |

| Dobeckan® FT 2002/…EK | 30/70/120/ 250/350 mPa.s 23°C | 180 | 30 min / 130°C or 15 min / 140°C | Single component, UL recognised, unsaturated polyester-imide, contains styrene, good bond strength, for household machines, starter motors and dynamos. For trickle application. |

| Aquanel® 014-3997/40 | 35 - 45 s B2 Cup 21°C | 180 | 3 h / 160°C | Single component, solventless emulsion, zero VOC, high bond strength, high chemical and moisture resistance, for the impregnation of stators, rotors and small transformers. For dip, hot dip and dip-roll application. |