In the Electronics industry miniaturization and higher power levels are key trends, with electronic parts becoming more densely populated with heat generating components. Usage of higher power levels also increases the heat generation.

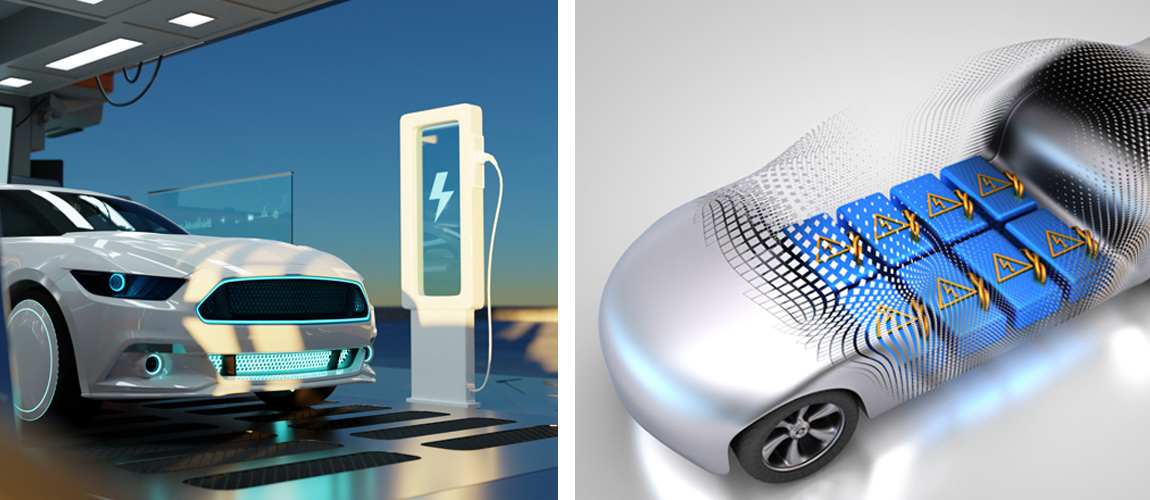

In the area of eMobility there’s the trend to smaller, lighter batteries, higher power-density and faster charging times. Excessive heat is generated during charging and discharging of the battery, which needs to be managed. The power electronic components and chargers in the electric vehicle also rely on higher power-density levels which leads to increased heat generation.

ELANTAS has developed a range of thermally conductive resins, based on various chemistries. This newsletter describes a range of thermally conductive, electrically insulating Thermal Interface Materials (TIM) based on silicone chemistry. Those products are available either as easily flowing and self levelling potting and also as more viscous gap fillers.

The below products have in common the following properties:

- 2-component silicone resins, mixing ratio 1:1

- Temperature range -50°C to +200°C

- Excellent electrical insulation

- Self-extinguishing properties (UL 94 V-0 certificate pending)

| Product | Thermal Conductivity W/m K | Hardness Shore | Application and Cure | Special Features |

| FS26 OP 0012 | 2.6 | 00 ~60 | Gap Filler Room temperature cure | Passed 2000 h 85% r.h. @85°C high Elongation |

| CS 26 AV 0012 | 2.6 | A ~60 | Potting resin, self-leveling Room temperature cure | Low CTE Good adhesion with heat cure |

| CS15 AV 0032 | 1.5 | A ~40 | Potting resin, easily flowing and self-leveling Room temperature cure | Excellent T-shock resistance -40°C / + 125°C Excellent adhesion with heat cure |

All above products are produced on industrial scale and can readily be samples. For any questions on those products or sample requests, please contact us directly at bectron.ELANTAS.europe@altana.com